Labor to Replace Nose Gear Doors on Mooney

Shipping component for takeoff and landing and which supports the shipping while non in the air

This commodity is most aircraft landing gear. For the Devin the Dude album, see Landing Gear.

Landing gear is the undercarriage of an shipping or spacecraft and may be used for either takeoff or landing. For aircraft it is generally needed for both. It was also formerly called alighting gear past some manufacturers, such as the Glenn L. Martin Visitor. For aircraft, Stinton[1] makes the terminology stardom undercarriage (British) = landing gear (U.s.).

For aircraft, the landing gear supports the craft when information technology is not flying, assuasive it to take off, country, and taxi without impairment. Wheeled landing gear is the most mutual, with skis or floats needed to operate from snow/ice/water and skids for vertical operation on state. Faster aircraft accept retractable undercarriages, which fold away during flying to reduce drag.

Some unusual landing gear have been evaluated experimentally. These include: no landing gear (to save weight), made possible by operating from a catapult cradle and flexible landing deck:[2] air cushion (to enable operation over a broad range of ground obstacles and water/snow/water ice);[three] tracked (to reduce runway loading).[4]

For launch vehicles and spacecraft landers, the landing gear unremarkably only supports the vehicle on landing, and is non used for takeoff or surface movement.

Given their varied designs and applications, in that location exists dozens of specialized landing gear manufacturers. The three largest are Safran Landing Systems, Collins Aerospace (part of Raytheon Technologies) and Héroux-Devtek.

Aircraft [edit]

The landing gear represents two.5 to 5% of the maximum takeoff weight (MTOW) and 1.5 to 1.75% of the aircraft toll, only 20% of the airframe directly maintenance cost. A suitably-designed wheel tin support 30 t (66,000 lb), tolerate a ground speed of 300 km/h and roll a distance of 500,000 km (310,000 mi) ; information technology has a xx,000 hours time between overhaul and a lx,000 hours or 20 years life fourth dimension.[5]

Gear arrangements [edit]

- Airplanes

-

-

-

Wheeled undercarriages normally come up in two types:

- Conventional landing gear or "taildragger", where there are ii primary wheels towards the front of the aircraft and a unmarried, much smaller, wheel or sideslip at the rear. The same helicopter organisation is called tricycle tailwheel.[six]

- Tricycle undercarriage where there are two primary wheels (or wheel assemblies) under the wings and a third smaller wheel in the nose. The same helicopter arrangement is called tricycle nosewheel.

The taildragger organization was mutual during the early propeller era, as it allows more than room for propeller clearance. Most mod shipping have tricycle undercarriages. Taildraggers are considered harder to land and have off (because the organization is usually unstable, that is, a small deviation from straight-line travel will tend to increase rather than correct itself), and usually require special pilot training. A small tail cycle or slip/bumper may be added to a tricycle undercarriage to prevent damage to the underside of the fuselage if over-rotation occurs on take-off leading to a tail strike. Shipping with tail-strike protection include the B-29 Superfortress, Boeing 727 trijet and Concorde. Some aircraft with retractable conventional landing gear accept a fixed tailwheel. Hoerner[7] estimated the elevate of the Bf 109 fixed tailwheel and compared it with that of other protrusions such every bit the airplane pilot's awning.

A tertiary arrangement (known every bit tandem or bicycle) has the main and olfactory organ gear located fore and aft of the heart of gravity under the fuselage with outriggers on the wings. This is used when there is no convenient location on either side of the fuselage to attach the principal undercarriage or to store it when retracted. Examples include the Lockheed U-2 spy aeroplane and the Harrier Spring Jet. The Boeing B-52 uses a similar arrangement, except that the fore and aft gears each have two twin-cycle units side by side.

Quadricycle gear is similar to bike but with two sets of wheels displaced laterally in the fore and aft positions. Raymer[8] classifies the B-52 gear as quadricycle. The experimental Fairchild Ninety-120 Packplane had quadricycle gear located in the engine nacelles to permit unrestricted access beneath the fuselage for attaching a large freight container.[9]

Helicopters use skids, pontoons or wheels depending on their size and role.

- Helicopters

-

Retractable gear [edit]

Retraction of the landing gear of a Boeing 727 after accept-off

To decrease drag in flying undercarriages retract into the wings and/or fuselage with wheels flush with the surrounding surface or concealed behind affluent-mounted doors; this is called retractable gear. If the wheels don't retract completely but protrude partially exposed to the airstream, information technology is chosen a semi-retractable gear.

Most retractable gear is hydraulically operated, though some is electrically operated or even manually operated on very light shipping. The landing gear is stowed in a compartment called a wheel well.

Pilots confirming that their landing gear is down and locked refer to "three greens" or "three in the greenish.", a reference to the electrical indicator lights (or painted panels of mechanical indicator units) from the nosewheel/tailwheel and the two main gears. Blinking greenish lights or carmine lights signal the gear is in transit and neither upwardly and locked or downwards and locked. When the gear is fully stowed up with the up-locks secure, the lights ofttimes extinguish to follow the dark cockpit philosophy; some airplanes accept prepare indicator lights.[10]

Redundant systems are used to operate the landing gear and redundant main gear legs may also be provided so the aircraft can be landed in a satisfactory manner in a range of failure scenarios. The Boeing 747 was given four separate and independent hydraulic systems (when previous airliners had two) and iv main landing gear posts (when previous airliners had two). Safe landing would exist possible if two main gear legs were torn off provided they were on contrary sides of the fuselage.[eleven] In the case of ability failure in a calorie-free aircraft, an emergency extension arrangement is always available. This may exist a manually operated creepo or pump, or a mechanical gratuitous-fall mechanism which disengages the uplocks and allows the landing gear to fall nether gravity.

-

Retractable landing gear blitheness

Shock absorbers [edit]

Aircraft landing gear includes wheels equipped with solid shock absorbers on lite planes, and air/oil oleo struts on larger aircraft.

-

Oleo strut (pressurized gas or oil) with torque links

-

Oleo strut with abaft link

-

Rubber discs in compression with trailing link of a Mooney M20

-

Unproblematic spring steel bar, used on many light aircraft

-

Unproblematic steel tube

Large aircraft [edit]

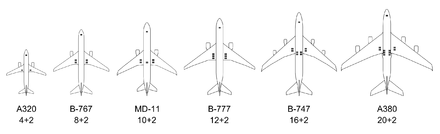

Wheel arrangements of large airliners

As aircraft weights have increased more wheels have been added and rails thickness has increased to keep within the rails loading limit. The Zeppelin-Staaken R.6, a large High german World War I long-range bomber of 1916, used eighteen wheels for its undercarriage, split between two wheels on its nose gear struts, and 16 wheels on its main gear units—separate into four side-by-side quartets each, two quartets of wheels per side—nether each tandem engine nacelle, to support its loaded weight of virtually 12 t (26,000 lb).

Multiple "tandem wheels" on an shipping—particularly for cargo aircraft, mounted to the fuselage lower sides equally retractable main gear units on modern designs—were first seen during World War Ii, on the experimental German Arado Ar 232 cargo shipping, which used a row of eleven "twinned" fixed bike sets directly under the fuselage centerline to handle heavier loads while on the ground.[12] Many of today'due south big cargo aircraft employ this arrangement for their retractable primary gear setups, usually mounted on the lower corners of the fundamental fuselage structure.

The prototype Convair XB-36 had most of its weight on two main wheels, which needed runways at to the lowest degree 22 in (56 cm) thick. Product shipping used two four-cycle bogies, allowing the aircraft to use any airfield suitable for a B-29.[13]

A relatively lite Lockheed JetStar business jet, with 4 wheels supporting 44,000 lb (20 t), needed a 10 in (25 cm) thick flexible asphalt pavement. The 210,000 lb (95 t) Boeing 727-200 with four tires on two legs main landing gears required a xx in (51 cm) thick pavement. The thickness rose to 25 in (64 cm) for a McDonnell Douglas DC-ten-10 with 443,000 lb (201 t) supported on eight wheels on two legs. The heavier, 558,000 lb (253 t), DC-10-30/40 were able to operate from the same thickness pavements with a third main leg for ten wheels, like the first Boeing 747-100, weighing 700,000 lb (320 t) on 4 legs and 16 wheels. The similar-weight Lockheed C-5, with 24 wheels, needs an 18 in (46 cm) pavement.[14]

The twin-wheel unit on the fuselage centerline of the McDonnell Douglas DC-10-30/xl was retained on the MD-11 airliner and the same configuration was used on the initial 275 t (606,000 lb) Airbus A340-200/300, which evolved in a complete four-cycle undercarriage bogie for the heavier 380 t (840,000 lb) Airbus A340-500/-600.[15] [16] The up to 775,000 lb (352 t) Boeing 777 has twelve main wheels on two three-axles bogies, similar the after Airbus A350.

The 575 t (1,268,000 lb) Airbus A380 has a 4-wheel bogie nether each fly with 2 sets of six-wheel bogies nether the fuselage.[17] The 640 t (i,410,000 lb) Antonov An-225, the largest cargo aircraft, had iv wheels on the twin-strut nose gear units like the smaller Antonov An-124, and 28 main gear wheels.[eighteen]

The 97 t (214,000 lb) A321neo has a twin-wheel main gear inflated to 15.vii bar (228 psi),[19] while the 280 t (620,000 lb) A350-900 has a 4-wheel main gear inflated to 17.1 bar (248 psi).[twenty]

-

Fly and fuselage undercarriages on a Boeing 747-400, presently before landing

STOL aircraft [edit]

STOL shipping have a college sink-charge per unit requirement if a carrier-type, no-flare landing technique has to exist adopted to reduce touchdown scatter. For example, the Saab 37 Viggen, with landing gear designed for a 5m/sec bear on, could use a carrier-type landing and HUD to reduce its scatter from 300 yard to 100m.[21]

The de Havilland Canada DHC-4 Caribou used long-stroke legs to land from a steep approach with no bladder.[22]

Operation from water [edit]

A flying boat has a lower fuselage with the shape of a gunkhole hull giving it buoyancy. Wing-mounted floats or chubby fly-like sponsons are added for stability. Sponsons are fastened to the lower sides of the fuselage.

A floatplane has two or three streamlined floats. Amphibious floats have retractable wheels for land operation.

An amphibious aircraft or amphibian commonly has two distinct landing gears, namely a "boat" hull/floats and retractable wheels, which allow it to operate from country or water.

Beaching gear is detachable wheeled landing gear that allows a non-amphibious floatplane or flying gunkhole to exist maneuvered on country. It is used for aircraft maintenance and storage and is either carried in the aircraft or kept at a slipway. Beaching gear may consist of individual detachable wheels or a cradle that supports the entire aircraft. In the former case, the beaching gear is manually fastened or detached with the shipping in the water; in the latter case, the shipping is maneuvered onto the cradle.

Helicopters are able to land on water using floats or a hull and floats.

For take-off a step and planing bottom are required to lift from the floating position to planing on the surface. For landing a cleaving action is required to reduce the impact with the surface of the water. A vee lesser parts the h2o and chines deflect the spray to prevent it damaging vulnerable parts of the aircraft. Additional spray control may exist needed using spray strips or inverted gutters. A step is added to the hull, only behind the center of gravity, to cease water clinging to the afterbody and then the shipping can accelerate to flight speed. The step allows air, known as ventilation air, to intermission the water suction on the afterbody.[23] Two steps were used on the Kawanishi H8K.[24] A step increases the drag in flight. The drag contribution from the step can be reduced with a fairing. A faired step was introduced on the Short SunderlandIII.[25]

One goal of seaplane designers was the development of an open up ocean seaplane capable of routine operation from very crude h2o. This led to changes in seaplane hull configuration. Loftier length/beam ratio hulls and extended afterbodies improved rough h2o capabilities.[26] A hull much longer than its width also reduced drag in flying.[27] An experimental development of the Martin Marlin, the Martin M-270, was tested with a new hull with a greater length/beam ratio of 15 obtained by adding vi feet to both the nose and tail.[27] Rough-sea capability can be improved with lower take-off and landing speeds considering impacts with waves are reduced. The Shin Meiwa United states-1A is a STOL amphibian with blown flaps and all command surfaces. The power to country and take-off at relatively depression speeds of about 45 knots and the hydrodynamic features of the hull, long length/beam ratio[28] and inverted spray gutter for example, permit operation in wave heights of fifteen feet.[29] The inverted gutters channel spray to the rear of the propeller discs.[30]

Low speed maneuvring is necessary between slipways and buoys and take-off and landing areas. Water rudders are used on seaplanes ranging in size from the Republic RC-3 Seabee to the Beriev A-twoscore[31] Hydro flaps were used on the Martin Marlin[32] and Martin SeaMaster. Hydroflaps, submerged at the rear of the afterbody, act as a speed restriction or differentially as a rudder. A fixed fin, known equally a skeg, has been used for directional stability. A skeg, was added to the second pace on the Kawanishi H8K flight boat hull.[33]

High speed impacts in rough water between the hull and wave flanks may be reduced using hydro-skis which hold the hull out of the water at higher speeds. Hydro skis replace the need for a boat hull and only require a plain fuselage which planes at the rear. Alternatively skis with wheels can be used for country-based shipping which showtime and finish their flying from a beach or floating barge. Hydro-skis with wheels were demonstrated every bit an all-purpose landing gear conversion of the Fairchild C-123, known every bit the Panto-base[34] Stroukoff YC-134. A seaplane designed from the outset with hydro-skis was the Convair F2Y Sea Dart epitome fighter. The skis incorporated small wheels, with a third wheel on the fuselage, for basis treatment.

In the 1950s hydro-skis were envisaged as a ditching aid for big piston-engined aircraft.[35] Water-tank tests washed using models of the Lockheed Constellation, Douglas DC-4 and Lockheed Neptune ended that chances of survival and rescue would be greatly enhanced by preventing critical damage associated with ditching.[36]

-

Kawanishi H8K showing two steps on the hull, a skeg at the 2nd step and spray strips under the forebody

-

Stroukoff YC-123E showing hydro-skis on pantobase landing gear

Shipboard operation [edit]

The landing gear on fixed-fly aircraft that country on aircraft carriers have a college sink-rate requirement because the shipping are flown onto the deck with no landing flare. Other features are related to catapult have-off requirements for specific aircraft. For case, the Blackburn Buccaneer was pulled downward onto its tail-skid to set the required nose-upwards mental attitude. The naval McDonnell Douglas F-4 Phantom II in U.k. service needed an extending nosewheel leg to set the wing attitude at launch.[37]

The landing gear for an aircraft using a ski-jump on take-off is subjected to loads of 0.5g which likewise last for much longer than a landing affect.[38]

Helicopters may have a deck-lock harpoon to anchor them to the deck.[39]

In-flight use [edit]

Some shipping have a requirement to utilise the landing-gear as a speed brake.

Flexible mounting of the stowed main landing-gear bogies on the Tupolev Tu-22R raised the aircraft palpitate speed to 550 kts. The bogies oscillated inside the nacelle under the control of dampers and springs as an anti-flutter device.[forty]

Gear common to different shipping [edit]

Some experimental shipping have used gear from existing aircraft to reduce program costs. The Martin-Marietta X-24 lifting body used the nose/main gear from the North American T-39 / Northrop T-38 and the Grumman X-29 from the Northrop F-5 / General Dynamics F-16.[41]

Other types [edit]

Skis [edit]

When an airplane needs to land on surfaces covered past snow, the landing gear commonly consists of skis or a combination of wheels and skis.

Detachable [edit]

Me 163B Komet with its two-bicycle takeoff "dolly" in place

Some shipping apply wheels for takeoff and jettison them when airborne for improved streamlining without the complexity, weight and infinite requirements of a retraction mechanism. The wheels are sometimes mounted onto axles that are part of a separate "dolly" (for master wheels simply) or "trolley" (for a three-wheel fix with a nosewheel) chassis. Landing is done on skids or like simple devices.

Historical examples include the "dolly"-using Messerschmitt Me 163 Komet rocket fighter,[42] the Messerschmitt Me 321 Gigant troop glider, and the first eight "trolley"-using prototypes[43] of the Arado Ar 234 jet reconnaissance bomber. The chief disadvantage to using the takeoff dolly/trolley and landing skid(due south) system on German World War 2 shipping – intended for a sizable number of belatedly-war German jet and rocket-powered military aircraft designs – was that aircraft would likely be scattered all over a military airfield later they had landed from a mission, and would be unable to taxi on their ain to an appropriately hidden "dispersal" location, which could hands exit them vulnerable to being shot up by attacking Centrolineal fighters. A related contemporary instance are the wingtip support wheels ("pogos") on the Lockheed U-2 reconnaissance aircraft, which autumn away after take-off and drop to globe; the aircraft then relies on titanium skids on the wingtips for landing.[ citation needed ]

Rearwards and sideways retraction [edit]

A Royal Air Forcefulness P-47 with its raked-forward master gear, and rearward-angled main wheel position (when retracted) indicated past the only-visible open up cycle door.

Some principal landing gear struts on World War II shipping, in guild to allow a single-leg master gear to more efficiently shop the cycle within either the wing or an engine nacelle, rotated the unmarried gear strut through a 90° angle during the rearwards-retraction sequence to allow the master wheel to rest "flat" above the lower end of the main gear strut, or affluent within the wing or engine nacelles, when fully retracted. Examples are the Curtiss P-40, Vought F4U Corsair, Grumman F6F Hellcat, Messerschmitt Me 210 and Junkers Ju 88. The Aero Commander family of twin-engined business organisation aircraft also shares this feature on the main gears, which retract aft into the ends of the engine nacelles. The rearward-retracting nosewheel strut on the Heinkel He 219[44] and the forward-retracting olfactory organ gear strut on the afterward Cessna Skymaster similarly rotated 90 degrees equally they retracted.[ citation needed ]

On nearly World War Two single-engined fighter aircraft (and even one German heavy bomber design) with sideways retracting main gear, the main gear that retracted into the wings was raked forward in the "downwards" position for meliorate footing handling, with a retracted position that placed the main wheels at some distance aft of their position when downairframe – this led to a complex angular geometry for setting up the "pintle" angles at the top ends of the struts for the retraction mechanism's centrality of rotation. with some aircraft, like the P-47 Thunderbolt and Grumman Bearcat, fifty-fifty mandating that the main gear struts lengthened as they were extended to requite sufficient ground clearance for their large iv-bladed propellers. One exception to the need for this complexity in many WW Two fighter aircraft was Nihon's famous Nothing fighter, whose main gear stayed at a perpendicular angle to the centerline of the shipping when extended, as seen from the side.

Variable axial position of main wheels [edit]

The principal wheels on the Vought F7U Cutlass could move twenty inches between a forward and aft position. The forward position was used for have-off to give a longer lever-arm for pitch command and greater nose-up attitude. The aft position was used to reduce landing bounce and reduce adventure of tip-back during ground handling.[45]

Tandem layout [edit]

The tandem or bicycle layout is used on the Hawker Siddeley Harrier, which has 2 main-wheels behind a single nose-wheel nether the fuselage and a smaller wheel near the tip of each wing. On 2nd generation Harriers, the wing is extended past the outrigger wheels to allow greater fly-mounted munition loads to be carried, or to permit fly-tip extensions to be bolted on for ferry flights.[46]

A tandem layout was evaluated by Martin using a peculiarly-modified Martin B-26 Marauder (the XB-26H) to evaluate its employ on Martin'due south first jet bomber, the Martin XB-48. This configuration proved and so manoeuvrable that information technology was also selected for the B-47 Stratojet.[47] It was also used on the U-ii, Myasishchev M-iv, Yakovlev Yak-25, Yak-28, Sud Aviation Vautour. A variation of the multi tandem layout is also used on the B-52 Stratofortress which has iv main cycle bogies (two forward and ii aft) underneath the fuselage and a pocket-size outrigger wheel supporting each fly-tip. The B-52's landing gear is too unique in that all four pairs of main wheels tin can be steered. This allows the landing gear to line upward with the runway and thus makes crosswind landings easier (using a technique called crab landing). Since tandem shipping cannot rotate for takeoff, the forrad gear must be long enough to requite the wings the right bending of set on during takeoff. During landing, the forrard gear must not touch the rail first, otherwise the rear gear will slam downwardly and may cause the aircraft to bounce and become airborne once again.[48]

Crosswind landing accommodation [edit]

The "castoring" main gear arrangement on a Blériot 11

One very early undercarriage incorporating castoring for crosswind landings was pioneered on the Bleriot 8 pattern of 1908. It was afterward used in the much more than famous Blériot Xi Channel-crossing shipping of 1909 and also copied in the earliest examples of the Etrich Taube. In this arrangement the main landing gear'due south stupor absorption was taken up by a vertically sliding bungee cord-sprung upper member. The vertical post along which the upper member slid to take landing shocks besides had its lower cease equally the rotation point for the forward end of the main wheel's break fork, allowing the master gear to pivot on moderate crosswind landings.[ citation needed ]

Manually-adjusted main-gear units on the B-52 can exist set for crosswind have-offs. It rarely has to be used from SAC-designated airfields which have major runways in the predominant strongest current of air direction.[49] The Lockheed C-5 Galaxy has swivelling 6-bike main units for crosswind landings and castoring rear units to prevent tire scrubbing on tight turns.[l]

"Kneeling" gear [edit]

Both the nosegear and the wing-mounted main landing gear of the Globe War Two German Arado Ar 232 cargo/ship aircraft were designed to kneel. This fabricated it easier to load and unload cargo, and improved taxiing over ditches and on soft basis.[51]

Some early U.S. Navy jet fighters were equipped with "kneeling" nose gear consisting of pocket-sized steerable auxiliary wheels on brusque struts located forward of the main nose gear, allowing the aircraft to exist taxied tail-high with the primary nose gear retracted. This feature was intended to enhance condom aboard shipping carriers by redirecting the hot frazzle blast upwards, and to reduce hangar space requirements past enabling the aircraft to park with its nose underneath the tail of a similarly equipped jet. Kneeling gear was used on the North American FJ-one Fury[52] and on early versions of the McDonnell F2H Banshee, but was found to be of little use operationally, and was omitted from afterwards Navy fighters.[53]

The nosewheel on the Lockheed C-5,[54] partially retracts against a bumper to assist in loading and unloading of cargo using ramps through the frontward, "tilt-up" hinged fuselage nose while stationary on the ground. The shipping as well tilts backwards.[55] The Messier twin-wheel main units fitted to the Transall and other cargo shipping can tilt forward or astern as necessary.[56]

The Boeing AH-64 Apache helicopter is able to kneel to fit within the cargo hold of a send aircraft and for storage.[57]

Tail back up [edit]

Shipping landing gear includes devices to prevent fuselage contact with the ground by tipping back when the aircraft is being loaded. Some commercial aircraft have used tail props when parked at the gate.[58] The Douglas C-54 had a critical CG location which required a ground handling strut.[59] The Lockheed C-130 and Boeing C-17 Globemaster 3 use ramp supports.[60]

Monowheel [edit]

To minimize elevate, modern gliders usually have a single wheel, retractable or fixed, centered nether the fuselage, which is referred to as monowheel gear or monowheel landing gear. Monowheel gear is also used on some powered aircraft, where drag reduction is a priority, such as the Europa Classic. Much like the Me 163 rocket fighter, some gliders from prior to the 2nd Globe War used a have-off dolly that was jettisoned on take-off; these gliders and so landed on a fixed skid.[61] This configuration is necessarily accompanied with a taildragger.

Helicopters [edit]

Lite helicopters utilize uncomplicated landing skids to save weight and toll. The skids may have attachment points for wheels then that they tin be moved for curt distances on the basis. Skids are impractical for helicopters weighing more than four tons. Some high-speed machines have retractable wheels, but most apply fixed wheels for their robustness, and to avoid the need for a retraction mechanism.[62]

Tailsitter [edit]

Experimental tailsitter aircraft use landing gear located in their tails for VTOL operation.

Light aircraft [edit]

For lite aircraft a type of landing gear which is economical to produce is a uncomplicated wooden arch laminated from ash, as used on some homebuilt aircraft. A like arched gear is often formed from spring steel. The Cessna Airmaster was among the first shipping to utilize leap steel landing gear. The principal advantage of such gear is that no other stupor-absorbing device is needed; the deflecting foliage provides the shock assimilation.[ citation needed ]

Folding gear [edit]

Ju 288 V1 beginning paradigm, showing its complex "folding" main undercarriage.

The limited infinite available to stow landing gear has led to many complex retraction mechanisms, each unique to a item aircraft. An early example, the German Bomber B combat aircraft design contest winner, the Junkers Ju 288, had a circuitous "folding" main landing gear unlike whatever other aircraft designed by either Centrality or Allied sides in the state of war: its single oleo strut was only attached to the lower finish of its Y-class main retraction struts, handling the twinned primary gear wheels, and folding past swiveling downwards and aftwards during retraction[63] to "fold" the maingear'due south length to shorten it for stowage in the engine nacelle it was mounted in.[64] However, the single pin-betoken design also led to numerous incidents of complanate maingear units for its prototype airframes.

Tracked [edit]

Increased contact area tin can be obtained with very large wheels, many smaller wheels or track-type gear. Tracked gear made by Dowty was fitted to a Westland Lysander in 1938 for taxi tests, then a Fairchild Cornell and a Douglas Boston.[65] Bonmartini, in Italia, fitted tracked gear to a Piper Cub in 1951.[66] Rail-type gear was also tested using a C-47, C-82 and B-50. A much heavier aircraft, an XB-36, was made available for further tests, although there was no intention of using it on production aircraft. The stress on the runway was reduced to one third that of the B-36 4-wheel bogie.[67] [68]

Ground wagon [edit]

Ground carriage is a long-term (after 2030) concept of flying without landing gear. It is one of many aviation technologies beingness proposed to reduce greenhouse gas emissions.[69] Leaving the landing gear on the footing reduces weight and drag. Leaving it behind after take-off was done for a different reason, ie with armed services objectives, during World War II using the "dolly" and "trolley" arrangements of the German Me 163B rocket fighter and Arado Ar 234A prototype jet recon-bomber.

Steering [edit]

There are several types of steering. Taildragger aircraft may exist steered by rudder alone (depending upon the prop wash produced past the aircraft to plough information technology) with a freely pivoting tail bike, or by a steering linkage with the tail wheel, or past differential braking (the utilize of independent brakes on reverse sides of the shipping to turn the aircraft past slowing one side more than sharply than the other). Shipping with tricycle landing gear usually have a steering linkage with the nosewheel (especially in big aircraft), but some let the nosewheel to pivot freely and use differential braking and/or the rudder to steer the aircraft, similar the Cirrus SR22.

Some aircraft require that the airplane pilot steer by using rudder pedals; others allow steering with the yoke or command stick. Some allow both. Still others accept a split up control, called a tiller, used for steering on the ground exclusively.[ citation needed ]

Rudder [edit]

When an aircraft is steered on the ground exclusively using the rudder, information technology needs a substantial airflow past the rudder, which can be generated either by the forward motility of the aircraft or past propeller slipstream. Rudder steering requires considerable practice to apply effectively. Although it needs airflow by the rudder, it has the advantage of non needing whatever friction with the ground, which makes information technology useful for aircraft on h2o, snowfall or ice.[ citation needed ]

Direct [edit]

The nose gear steering-bike (tiller) is visible equally a semi-circular bicycle to the left of the yoke in this photo of a Boeing 727 cockpit

Some aircraft link the yoke, control stick, or rudder directly to the bike used for steering. Manipulating these controls turns the steering cycle (the nose wheel for tricycle landing gear, and the tail wheel for taildraggers). The connexion may be a firm 1 in which whatsoever movement of the controls turns the steering wheel (and vice versa), or it may be a soft one in which a spring-like mechanism twists the steering wheel but does not force it to turn. The erstwhile provides positive steering but makes it easier to sideslip the steering wheel; the latter provides softer steering (making it easy to overcontrol) but reduces the probability of skidding. Aircraft with retractable gear may disable the steering machinery wholly or partially when the gear is retracted.[ citation needed ]

Differential braking [edit]

Differential braking depends on asymmetric application of the brakes on the main gear wheels to turn the shipping. For this, the aircraft must be equipped with split controls for the right and left brakes (commonly on the rudder pedals). The nose or tail wheel usually is not equipped with brakes. Differential braking requires considerable skill. In aircraft with several methods of steering that include differential braking, differential braking may be avoided considering of the clothing it puts on the braking mechanisms. Differential braking has the advantage of being largely contained of any motility or skidding of the olfactory organ or tailwheel.[ citation needed ]

Tiller [edit]

A tiller in an aircraft is a small bicycle or lever, sometimes accessible to one pilot and sometimes duplicated for both pilots, that controls the steering of the aircraft while it is on the ground. The tiller may be designed to piece of work in combination with other controls such equally the rudder or yoke. In large airliners, for example, the tiller is oft used as the sole means of steering during taxi, and then the rudder is used to steer during takeoff and landing, and then that both aerodynamic control surfaces and the landing gear can be controlled simultaneously when the aircraft is moving at aerodynamic speeds.[ commendation needed ]

Tires and wheels [edit]

The specified pick criterion, e.one thousand., minimum size, weight, or pressure, are used to select suitable tires and wheels from manufacturer's catalog and industry standards institute in the Aircraft Yearbook published by the Tire and Rim Association, Inc.[70]

Gear loading [edit]

The choice of the main cycle tires is made on the basis of the static loading case. The total master gear load

where

The selection of the nose wheel tires is based on the olfactory organ wheel load

where

To ensure that the rated loads will not be exceeded in the static and braking conditions, a seven percent safety factor is used in the calculation of the applied loads.

Inflation pressure [edit]

Provided that the wheel load and configuration of the landing gear remain unchanged, the weight and volume of the tire volition decrease with an increase in inflation force per unit area.[71] From the flotation standpoint, a decrease in the tire contact expanse will induce a higher begetting stress on the pavement which may reduce the number of airfields available to the aircraft. Braking will also become less effective due to a reduction in the frictional forcefulness between the tires and the basis. In improver, the decrease in the size of the tire, and hence the size of the wheel, could pose a problem if internal brakes are to be fitted inside the bike rims. The arguments against higher pressure are of such a nature that commercial operators generally prefer the lower pressures in guild to maximize tire life and minimize runway stress. To prevent punctures from stones Philippine Airlines had to operate their Hawker Siddeley 748 shipping with pressures as depression as the tire manufacturer would permit.[72] However, too low a pressure can lead to an blow as in the Nigeria Airways Flight 2120.

A rough general dominion for required tire pressure is given by the manufacturer in their catalog. Goodyear for instance advises the pressure to exist 4% college than required for a given weight or as fraction of the rated static load and inflation.[73]

Tires of many commercial aircraft are required to exist filled with nitrogen, and non later on diluted with more than 5% oxygen, to prevent auto-ignition of the gas which may result from overheating brakes producing volatile vapors from the tire lining.[74]

Naval aircraft employ different pressures when operating from a carrier and ashore. For case, the Northrop Grumman East-2 Hawkeye tire pressures are 260 psi on ship and 210 psi aground.[75] En-route deflation is used in the Lockheed C-v Galaxy to adapt airfield conditions at the destination simply adds excessive complexity to the landing gear and wheels[76]

Future developments [edit]

Airport customs racket is an environmental issue which has brought into focus the contribution of aerodynamic racket from the landing gear. A NASA long-term goal is to confine shipping objectional noise to within the airdrome boundary. During the arroyo to land the landing gear is lowered several miles from touchdown and the landing gear is the dominant airframe dissonance source, followed past deployed highlift devices. With engines at a reduced ability setting on the approach it is necessary to reduce airframe noise to make a significant reduction to total aircraft noise.[77] [78] The add-on of add together-on fairings is one approach for reducing the noise from the landing gear with a longer term approach to accost noise generation during initial pattern.[79]

Airline specifications crave an airliner to reach upwardly to 90,000 have-offs and landings and ringlet 500,000 km on the ground in its lifetime. Conventional landing gear is designed to blot the free energy of a landing and doesn't perform well at reducing ground-induced vibrations in the airframe during landing footing roll, taxi and accept-off. Airframe vibrations and fatigue damage can be reduced using semi-agile oleos which vary damping over a wide range of ground speeds and runway quality.

Accidents [edit]

JetBlue Airways Flight 292, an Airbus A320, making an emergency landing on runway 25L at Los Angeles International Airport in 2005 later the front landing gear malfunctioned

Malfunctions or human errors (or a combination of these) related to retractable landing gear have been the cause of numerous accidents and incidents throughout aviation history. Lark and preoccupation during the landing sequence played a prominent function in the approximately 100 gear-up landing incidents that occurred each yr in the United States between 1998 and 2003.[eighty] A gear-up landing, too known equally a belly landing, is an accident that results from the pilot forgetting to lower the landing gear, or being unable to do so considering of a malfunction. Although rarely fatal, a gear-upwardly landing can be very expensive if information technology causes all-encompassing airframe/engine harm. For propeller-driven shipping a prop strike may require an engine overhaul.

Some aircraft have a stiffened fuselage underside or added features to minimize structural impairment in a wheels-up landing. When the Cessna Skymaster was converted for a military spotting role (the O-2 Skymaster), fiberglass railings were added to the length of the fuselage; they were adequate to support the aircraft without impairment if it was landed on a grassy surface.[ citation needed ]

The Bombardier Nuance 8 is notorious for its landing gear issues. In that location were iii incidents involved, all of them involving Scandinavian Airlines, flights SK1209, SK2478, and SK2867. This led to Scandinavian retiring all of its Dash 8s. The cause of these incidents was a locking mechanism that failed to work properly. This likewise caused concern for the aircraft for many other airlines that found similar problems, Bombardier Aerospace ordered all Nuance 8s with 10,000 or more hours to be grounded, it was soon found that nineteen Horizon Airlines Dash 8s had locking mechanism bug, so did 8 Austrian Airlines planes, this did crusade several hundred flights to be canceled.[ citation needed ]

On September 21, 2005, JetBlue Airways Flying 292 successfully landed with its nose gear turned ninety degrees sideways, resulting in a shower of sparks and flame after touchdown.[81]

On November 1, 2011, LOT Polish Airlines Flight LO16 successfully belly landed at Warsaw Chopin Airport due to technical failures; all 231 people on lath escaped without injury.[82]

Emergency extension systems [edit]

In the issue of a failure of the shipping's landing gear extension mechanism a backup is provided. This may be an alternate hydraulic system, a hand-crank, compressed air (nitrogen), pyrotechnic or free-fall arrangement.[83]

A free-fall or gravity drop system uses gravity to deploy the landing gear into the down and locked position. To accomplish this the pilot activates a switch or mechanical handle in the cockpit, which releases the up-lock. Gravity so pulls the landing gear down and deploys it. Once in position the landing gear is mechanically locked and prophylactic to use for landing.[84]

Ground resonance in rotorcraft [edit]

Rotorcraft with fully articulated rotors may feel a dangerous and self-perpetuating phenomenon known as footing resonance, in which the unbalanced rotor system vibrates at a frequency congruent with the natural frequency of the airframe, causing the entire aircraft to violently milk shake or wobble in contact with the ground.[85] [86] Ground resonance occurs when shock is continuously transmitted to the turning rotors through the landing gear, causing the angles between the rotor blades to become uneven; this is typically triggered if the aircraft touches the footing with forrard or lateral motion, or touches downwards on i corner of the landing gear due to sloping ground or the craft's flight attitude.[85] [86] The resulting violent oscillations may cause the rotors or other parts to catastrophically neglect, detach, and/or strike other parts of the airframe; this tin can destroy the shipping in seconds and critically endanger persons unless the pilot immediately initiates a takeoff or closes the throttle and reduces rotor pitch.[85] [86] Footing resonance was cited in 34 National Transportation Condom Board incident and accident reports in the United States betwixt 1990 and 2008.[85]

Rotorcraft with fully articulated rotors typically take stupor-absorbing landing gear designed to prevent footing resonance; however, poor landing gear maintenance and improperly inflated tires may contribute to the phenomenon.[85] Helicopters with slip-blazon landing gear are less decumbent to basis resonance than those with wheels.[86]

Stowaways [edit]

Unauthorized passengers have been known to stowaway on larger aircraft by climbing a landing gear strut and riding in the compartment meant for the wheels. There are extreme dangers to this practice, with numerous deaths reported. Dangers include a lack of oxygen at high altitude, temperatures well below freezing, beat out injury or death from the gear retracting into its bars space, and falling out of the compartment during takeoff or landing.[87]

Spacecraft [edit]

Launch vehicles [edit]

Falcon 9 descending, just after landing legs were extended, May 2017.

Landing gear has traditionally non been used on the vast bulk of launch vehicles, which take off vertically and are destroyed on falling back to earth. With some exceptions for suborbital vertical-landing vehicles (east.g., Masten Xoie or the Armadillo Aerospace' Lunar Lander Challenge vehicle), or for spaceplanes that employ the vertical takeoff, horizontal landing (VTHL) approach (eastward.g., the Space Shuttle orbiter, or the USAF X-37), landing gear have been largely absent-minded from orbital vehicles during the early decades since the advent of spaceflight engineering, when orbital space send has been the exclusive preserve of national-monopoly governmental infinite programs.[88] Each spaceflight system through 2015 had relied on expendable boosters to begin each ascent to orbital velocity.

Advances during the 2010s in private space transport, where new contest to governmental space initiatives has emerged, have included the explicit design of landing gear into orbital booster rockets. SpaceX has initiated and funded a multimillion-dollar reusable launch system development programme to pursue this objective. As part of this program, SpaceX built, and flew eight times in 2012–2013, a starting time-generation examination vehicle called Grasshopper with a large fixed landing gear in order to test low-distance vehicle dynamics and control for vertical landings of a most-empty orbital beginning stage.[89] [90] A second-generation test vehicle called F9R Dev1 was congenital with extensible landing gear. The prototype was flown four times—with all landing attempts successful—in 2014 for low-altitude tests before being self-destructed for safety reasons on a fifth examination flight due to a blocked engine sensor port.[91] [92]

The orbital-flight version of the test vehicles–Falcon nine and Falcon Heavy—includes a lightweight, deployable landing gear for the booster phase: a nested, telescoping piston on an A-frame. The total span of the iv carbon fiber/aluminum extensible landing legs[93] [94] is approximately 18 metres (60 ft), and weigh less than 2,100 kilograms (four,600 lb); the deployment system uses high-pressure level Helium as the working fluid.[95] The get-go test of the extensible landing gear was successfully accomplished in Apr 2014 on a Falcon ix returning from an orbital launch and was the get-go successful controlled ocean soft touchdown of a liquid-rocket-engine orbital booster.[96] [97] Later a single successful booster recovery in 2015, and several in 2016, the recovery of SpaceX booster stages became routine by 2017. Landing legs had get an ordinary operational part of orbital spaceflight launch vehicles.

The newest launch vehicle under development at SpaceX—the Starship—is expected to have landing legs on its first stage called Super Heavy[98] similar Falcon 9 but too has landing legs on its reusable 2d stage, a showtime for launch vehicle second stages. The first epitome of Starship—Starhopper, built in early 2019—had 3 fixed landing legs with replaceable daze absorbers.[99] In gild to reduce mass of the flight vehicle and the payload penalty for a reusable design, the long-term plan is for vertical landing of the Super Heavy to land directly back at the launch site on a special ground equipment that is role of the launch mount,[98] but initial testing of the big booster in 2020 is expected to occur with landing legs.

Landers [edit]

Spacecraft designed to land safely on extraterrestrial bodies such every bit the Moon or Mars are known every bit either legged landers (for example the Apollo Lunar Module) or pod landers (for instance Mars Pathfinder) depending on their landing gear. Pod landers are designed to land in any orientation after which they may bounce and roll before coming to remainder at which fourth dimension they have to exist given the right orientation to role. The whole vehicle is enclosed in crushable material or airbags for the impacts and may have opening petals to right information technology.[100]

Features for landing and movement on the surface were combined in the landing gear for the Mars Science Laboratory.[101]

For landing on low-gravity bodies landing gear may include hold-downward thrusters, harpoon anchors and foot-pad screws, all of which were incorporated in the design of comet-lander Philae for back-up.[102] In the example of Philae, even so, both harpoons and the hold-down thruster failed, resulting in the craft bouncing before landing for adept at a not-optimal orientation.[103]

-

Apollo Lunar Module showing landing gear legs

-

The Mars Pathfinder lander during a footing test encased in its cluster of air numberless

-

Comet lander Philae showing anchoring harpoons (ii) and pes-pad screws (3)

-

Mars Science Laboratory showing rover'due south wheels which acted as landing gear for initial touchdown

-

Mars Pathfinder showing ane of iii petals and deflated airbags

Run into also [edit]

- Dayton-Wright RB-1 Racer, an early example of an airplane with retractable landing gear.

- Landing gear extender

- Tundra tire, a low-pressure landing gear tire allowing landings on rough surfaces

- Undercarriage arrangements of jetliners and other aircraft.

- Verville Racer Aircraft, an early example of an airplane with retractable landing gear.

References [edit]

- ^ The Design Of The Aeroplane, Darrol Stinton 1983, ISBN 0-632-01877-1, p.63

- ^ Farnborough and the Fleet Air Arm, Geoffrey Cooper 2008, ISBN 978 1 85780 306 8, pp. 197-205

- ^ Power The Pratt and Whitney Canada Story, Kenneth H> Sullivan and Larry Milberry 1989, ISBN 0-921022-01-8, pp. 193/194

- ^ Magnesium Clouded The Story of the Convair B-36, Dennis R. Jenkins2001-2002, ISBN 978-1-58007-129-1, p. 17

- ^ Gerd Roloff (April 2002). "Shipping Landing Gear" (PDF). Airbus-Deutschland GmbH. The Development of a Organisation. Archived from the original (PDF) on 2008-11-22. Retrieved 2017-05-23 .

- ^ https://apps.dtic.mil/dtic/tr/fulltext/u2/a105512.pdf, Tabular array i

- ^ http://ftp.demec.ufpr.br/disciplinas/TM240/Marchi/Bibliografia/Hoerner.pdf p.14-iii

- ^ https://soaneemrana.org/onewebmedia/AIRCRAFT%20DESIGN%20%3B%20A%20Conceptual%20Approach%20BY%20DANIEL%20P%20RAYMER.pdf Archived 2019-07-04 at the Wayback Motorcar, p.230

- ^ "Aviation Week 1950-09-11". September eleven, 1950 – via Internet Annal.

- ^ AMT Airframe Handbook Volume 2 (FAA-H-8083-31). Washington DC: FAA. pp. 13–24.

- ^ 747 Creating The Earth's First Jumbo Jet And Other Adventures From A Life In Aviation, Joe Sutter 2006, ISBN 0 06 088241 7, p. 129

- ^ Sengfelder, Günther (1993). German Aircraft Landing Gear. Atglen, PA USA: Schiffer Publishing. pp. xl–42. ISBN0-88740-470-seven.

A significant reward of this [Ar 232] aircraft was its rough-field landing gear. With the landing gear in the compressed position, the eleven pairs of wheels mounted on independently-sprung legs below the fuselage, together with the broad-track main landing gear (8.iv meter, 27 ft 6 in wheel track) and the levered-interruption nose wheel, gave the aircraft outstanding rough field capabilities.

- ^ Magnesium Overcast The Story of the Convair B-36, Dennis R. Jenkins 2001-2002, ISBN 1 58007 042 6, pp. xiv/xv

- ^ Egbert Torenbeek (1976), Synthesis of Subsonic Aeroplane Blueprint, Delft Academy Press, Fig. 10-5

- ^ Airbus A340 And A330, Guy Norris and Mark Wagner 2001, ISBN 0 7603 0889 6, p.29

- ^ Civil Aircraft In Colour, Hiroshi Seo 1984, ISBN 0 7106 0346 0, p. xi

- ^ Airbus A380 Superjumbo Of The 21 St Century, Guy Norris ans Mark Wagner 2010, ISBN 978 0 7603 3838 four, p. 135

- ^ Tarantola, Andrew. "The Earth's Largest Cargo Plane Can Swallow a 737 Whole". gizmodo.com.

- ^ "A321 aircraft characteristics" (PDF). Airbus. April 2020.

- ^ "A350 shipping characteristics" (PDF). Airbus. May 2020.

- ^ "svenska flygmotor | gainsay biplane | viggen | 1967 | 0650 | Flight Archive". flightglobal.com. 1967. Retrieved 22 November 2019.

- ^ "de havilland | 1961 | 0430 | Flying Annal".

- ^ Havens, Robert F. (April i, 1945). "Tank tests of a flying-boat model equipped with several types of fairing designed to reduce the air elevate of the main step" (PDF) – via ntrs.nasa.gov.

- ^ Ferguson, J. A.; Seibels, R. E.; Corber, R. J. (September one, 1949). "Flight tests of the hydrodynamic characteristics of a Japanese "Emily" flying gunkhole" – via ntrs.nasa.gov.

- ^ https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19930093610.pdf, p.25

- ^ https://apps.dtic.mil/dtic/tr/fulltext/u2/650769.pdf

- ^ a b "Aviation Calendar week 1952-06-23". June 23, 1952 – via Internet Archive.

- ^ https://www.scribd.com/document/169396592/Is-There-a-Part-for-Modern-Twenty-four hours-Seaplanes-in-Open-Bounding main-Search-and-Rescue-pdf, p.35

- ^ https://apps.dtic.mil/dtic/tr/fulltext/u2/a476447.pdf, p.13

- ^ https://archive.org/details/DTIC_ADA476447 p.13

- ^ Goebel, Greg (ane April 2021). "Beriev A-xl, Be-200, & Be-103 Flying Boats". airvectors.cyberspace. Archived from the original on 22 Jan 2022. Retrieved 5 February 2022.

- ^ https://calhoun.nps.edu/handle/10945/14093, p.four

- ^ https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19930083200.pdf, Figure 3 (d)

- ^ "Aircraft landing gear".

- ^ https://www.biodiversitylibrary.org/bibliography/38156#/summary, p.189

- ^ Fisher, Lloyd J. (April 25, 1950). "Model ditching investigations of three airplanes equipped with hydro-skis" – via ntrs.nasa.gov.

- ^ "1971 | 0062 | Flight Archive".

- ^ ""Ski Spring" Harrier". FLIGHT International: 1630–1635. 4 December 1976.

- ^ "New life for lynx". Flightglobal.com. July 16, 2002.

- ^ Tupolev Tu-22 Blinder, Sergey Burdin & Alan E Dawes2006, ISBN 1 84415 241 3, p.71

- ^ The 10-Planes X-1 To X-31, Jay Miller 1988, ISBN 0 517 56749 0, p.169 and 190

- ^ Canada Aviation and Space Museum (n.d.). "Messerschmitt Me 163B-1a Komet". Retrieved 13 May 2012.

- ^ "Aerostories: Arado 234, July - August 1944: no ordinary missions." Aerostories. Retrieved: sixteen March 2016.

- ^ Sengfelder, Günther (1993). German Aircraft Landing Gear. Atglen, PA United states: Schiffer Publishing. pp. 141–142. ISBN0-88740-470-seven.

During retraction the nosewheel had to turn through 90 degrees, which was accomplished by means of a mechanism in the head of the wheel fork. On retraction, a spring-loaded level with pulley, which express deflection to 60 degrees past ways of a locking claw and stop, was folded into the fuselage and turned through xc degrees after making contact with a guide.

- ^ U.Southward. Naval Air Superiority Evolution Of Shipborne Jet Fighters 1943-1962, Tommy H. Thomason 2007, ISBN 978 1 58007 110 9, p.106/107

- ^ Dow, Andrew (February 19, 2015). Pegasus: The Centre of the Harrier (two ed.). Pen and Sword. p. 312. ISBN978-1-84884-042-3.

- ^ Air Force Legends Number 201 The Martin XB-51, Scott Libis, 1998, ISBN 0 942612 00 0, p. 2

- ^ The B-47. Lookout Mountain Air Force Station. 1950.

- ^ Flying American Combat Shipping The Common cold War, Edited past Robin Higham 2005, ISBN 978 0 8117 3238 iii, p.32

- ^ http://world wide web.air.flyingway.com/books/Airframe-Stuctural-Pattern.pdf p.436

- ^ Sengfelder, Günther (1993). German language Aircraft Landing Gear. Atglen, PA USA: Schiffer Publishing. pp. 40–42. ISBN0-88740-470-7.

A significant reward of this [Ar 232] aircraft was its rough-field landing gear. With the landing gear in the compressed position, the eleven pairs of wheels mounted on independently-sprung legs beneath the fuselage, together with the wide-rails main landing gear (8.4 meter, 27 ft 6 in cycle rails) and the levered-suspension nose wheel, endowed the aircraft with outstanding rough field capabilities.

- ^ "North American NA-141 Fury (FJ-1)". Yanks Air Museum. Archived from the original on eighteen December 2015. Retrieved 23 January 2016.

- ^ Mesko, Jim (2002). FH Phantom/F2H Banshee in action. Carrollton, Texas, USA: Squadron/Signal Publications, Inc. p. 12. ISBN0-89747-444-9.

- ^ http://www.air.flyingway.com/books/Airframe-Stuctural-Design.pdf, p. 435

- ^ http://everyspec.com/MIL-STD/MIL-STD-1700-1799/MIL-STD-1791C_55770/ FIGURE B-vi

- ^ http://www.air.flyingway.com/books/Airframe-Stuctural-Design.pdf, pp. 432, 434

- ^ Jane'due south All The World's Shipping 1982–83, John Due west.R. Taylor, ISBN 0 7106 0748 2, p. 394

- ^ http://www.dept.aoe.vt.edu/~stonemason/Mason_f/M96SC01.pdf

- ^ http://everyspec.com/MIL-SPECS/MIL-SPECS-MIL-L/MIL-Fifty-87139_8546/ p.31

- ^ http://everyspec.com/MIL-STD/MIL-STD-1700-1799/MIL-STD-1791C_55770/ TABLE III, Effigy B-71 and B-95

- ^ "Europa XS Monowheel Overview". Europa Aircraft Ltd. 2011. Archived from the original on v December 2008. Retrieved 13 May 2012.

- ^ Cox, Taylor. "Skids or Wheels?". helis.com . Retrieved three March 2018.

- ^ "Ju288の脚". www5a.biglobe.ne.jp.

- ^ Sengfelder, Günther (1993). German language Aircraft Landing Gear. Atglen, PA USA: Schiffer Publishing. pp. 175–177. ISBN0-88740-470-7.

The Ju 288's landing gear was most innovative in its pattern. A Y-shaped bearer was mounted in the engine nacelle with its upper arms hinged. At the bottom terminate of this bearer was the stupor absorber leg, which was likewise hinged. 2 double-brake wheels, with (metric) size 1015 x 380 tires, were mounted on the cross-beam. During the retraction cycle a folding strut was raised by a hydraulic jack. The lesser function of the folding strut drew the Y-bearer upwardly. Functioning via a lever-and-gear system, a pushrod positioned parallel to the Y-bearer acted upon another gear segment mounted to the oleo leg's hinge pin and rotated it virtually this as the Y-bearer was fatigued upwards.

- ^ https://www.flightglobal.com/pdfarchive/view/1943/1943 - 2372.html

- ^ https://www.flightglobal.com/pdfarchive/view/1971/1971 - 2630.html

- ^ Magnesium Clouded The Story of the Convair B-36, Dennis R. Jenkins 2001-2002, ISBN 978 ane 58007 129 1, p.17

- ^ "History of Aircraft Track Landing Gear". Air Forcefulness Materiel Command.

- ^ International Air Send Clan (June 2014). "Engineering Roadmap" (PDF). iata.org. Archived from the original (PDF) on fourteen May 2014. Retrieved 28 February 2022.

- ^ https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19970031272.pdf, p.30

- ^ a b c d Chai, Sonny T.; Mason, William H. (September 1, 1996). Landing Gear Integration in Aircraft Conceptual Design (PDF). NASA CR-205551. Vol. MAD 96-09-01 (revised March 1, 1997 ed.). Blacksburg, Virginia: Virginia Polytechnic Institute and State Academy. OCLC 39005288. Retrieved 25 October 2018 – via NASA.

- ^ "Test Airplane pilot" Tony Blackman, Chow Street Publishing 2009, ISBN 9781906502362, p.177

- ^ [i] Goodyear Tire & Rubber Co., Retrieved: 26 January 2012.

- ^ [two] FAA Ruling: "Use of Nitrogen or Other Inert Gas for Tire inflation in Lieu of Air" Docket No. 26147 Amendment No. 25-78 RIN 2120-AD87

- ^ Jane'due south All The World'south Aircraft 1982-1983, Edited past John Due west. R. Taylor, ISBN 0 86720 621 7, p.376

- ^ MIL87139, p.24

- ^ http://digitool.library.mcgill.ca/webclient/StreamGate?folder_id=0&dvs=1575683504592~592, p.5

- ^ Powell, Clemans A.; Preisser, John S. (January 2000). "NASA'due south Subsonic Jet Transport Dissonance Reduction Enquiry" (PDF).

- ^ http://resource.isvr.soton.ac.uk/staff/pubs/PubPDFs/Pub12391.pdf

- ^ The Office of the NASA Aviation Prophylactic Reporting Arrangement (Jan 2004). "Prepare Checkup" (PDF). Call Dorsum ASRS. NASA (292). Retrieved one April 2012.

- ^ https://www.ntsb.gov/_layouts/ntsb.aviation/brief2.aspx?ev_id=20050927X01540&ntsbno=LAX05IA312&akey=i

- ^ Scislowska, Monika (three November 2011). "Warsaw airport dorsum to work after plane emergency". NBC News . Retrieved 13 January 2012.

- ^ "Boeing 757 Landing Gear". Biggles Software. 29 December 2011. Archived from the original on 24 March 2009. Retrieved 13 May 2012.

- ^ Stellan F. Hilmerby (24 November 2009). "Landing Gear". Stellans Flightsim Pages . Retrieved 13 May 2012.

- ^ a b c d e Garrison, Peter (December 2008). "How Things Piece of work: Ground Resonance". airspacemag.com. Air and Space Magazine. Retrieved vi Nov 2018.

- ^ a b c d "Rotorcraft Flying Handbook" (PDF). faa.gov. Federal Aviation Administration. 2000. pp. 11–7. Retrieved half dozen November 2018.

- ^ "Wheel-well Stowaways Gamble Lethal Levels of Hypoxia and Hypothermia" (PDF). Flight Rubber Foundation. May–June 1997. Retrieved 15 June 2015.

- ^ Hanlon, Michael (2013-06-eleven). "Curlicue up for the Red Planet". The Telegraph. Archived from the original on 2013-06-12. Retrieved 2013-ten-26 .

the infinite race is flaring dorsum into life, and information technology's not massive institutions such equally Nasa that are in the running. The erstwhile view that human space flying is so complex, difficult and expensive that only huge government agencies could hope to accomplish it is being disproved by a new breed of flamboyant infinite privateers, who are planning to send humans out across the Earth'due south orbit for the showtime fourth dimension since 1972.

- ^ Foust, Jeff (2013-10-18). "SpaceX wrapping up Falcon 9 2d stage investigation equally it moves on from Grasshopper". NewSpace Journal . Retrieved 2013-ten-26 .

- ^ Klotz, Irene (2013-10-17). "SpaceX Retires Grasshopper, New Test Rig To Fly in December". Space News. Archived from the original on Oct 21, 2013. Retrieved 2013-ten-26 .

- ^ Foust, Jeff (2014-08-23). "Falcon 9 test vehicle destroyed in accident". NewSpace Journal. Retrieved 2014-08-23 .

- ^ Leone, Dan (2013-05-13). "SpaceX Leases Pad in New Mexico for Next Grasshopper Tests". SpaceNews. Archived from the original on September three, 2013. Retrieved 2013-08-03 .

- ^ "Landing Legs". SpaceX News. 2013-07-29. Retrieved 2013-07-30 .

The Falcon 9 showtime stage carries landing legs which volition deploy after stage separation and allow for the rocket's soft return to Earth. The four legs are fabricated of land-of-the-fine art carbon fiber with aluminum honeycomb. Placed symmetrically effectually the base of operations of the rocket, they stow along the side of the vehicle during liftoff and later extend outward and down for landing.

- ^ "Landing Legs". SpaceX News. 2013-04-12. Retrieved 2013-08-02 .

The Falcon Heavy first stage center cadre and boosters each carry landing legs, which will country each cadre safely on Globe after takeoff. Later on the side boosters carve up, the center engine in each will burn to control the booster'due south trajectory safely away from the rocket. The legs will and so deploy as the boosters plow back to Earth, landing each softly on the ground. The heart core volition go along to fire until stage separation, after which its legs will deploy and land it back on Globe too. The landing legs are fabricated of state-of-the-fine art carbon fiber with aluminum honeycomb. The four legs stow along the sides of each core during liftoff and later extend outward and downwardly for landing.

- ^ Lindsey, Clark (2013-05-02). "SpaceX shows a leg for the "F-niner"" . Retrieved 2013-05-02 .

F9R (pronounced F-niner) shows a little leg. Design is a nested, telescoping piston west A frame... High pressure helium. Needs to be ultra light.

- ^ Belfiore, Michael (Apr 22, 2014). "SpaceX Brings a Booster Safely Back to Earth". MIT Technology Review . Retrieved April 25, 2014.

- ^ Norris, Guy (April 28, 2014). "SpaceX Plans For Multiple Reusable Booster Tests". Aviation Week . Retrieved April 27, 2014.

The April 17 F9R Dev ane flight, which lasted under 1 min., was the kickoff vertical landing examination of a production-representative recoverable Falcon 9 v1.ane kickoff stage, while the April 18 cargo flying to the ISS was the first opportunity for SpaceX to evaluate the pattern of foldable landing legs and upgraded thrusters that control the stage during its initial descent.

- ^ a b Musk, Elon (i March 2018). "Making Life Multi-Planetary". New Space. 6 (1): 2–xi. Bibcode:2018NewSp...6....2M. doi:10.1089/infinite.2018.29013.emu.

- ^ Baylor, Michael (2 June 2019). "SpaceX readying Starhopper for hops in Texas as Pad 39A plans materialize in Florida". NASASpaceFlight.com . Retrieved three June 2019.

- ^ https://www.cambridge.org/core/books/planetary-landers-and-entry-probes/8DE95EEE4A7A3EF7820792504AC1C5E2, pp.72,74,75,147

- ^ https://www.cambridge.org/core/books/planetary-landers-and-entry-probes/8DE95EEE4A7A3EF7820792504AC1C5E2, p.76

- ^ https://www.cambridge.org/core/books/planetary-landers-and-entry-probes/8DE95EEE4A7A3EF7820792504AC1C5E2, Affiliate 26

- ^ "Issues hit Philae subsequently historic first comet landing".

External links [edit]

- "Standard Naming Convention for Aircraft Landing Gear Configurations" (PDF). FAA. October 6, 2005.

- How to change the landing gear of an Airbus A380 (YouTube). Emirates Airline. May 28, 2018. Archived from the original on 2021-xi-08.

complete replacement of landing gear systems

- Scholz, Dieter. "Summary: Aircraft Design in a Nutshell" (PDF). Shipping Blueprint: Lecture Notes. Hamburg, Germany: Hamburg Open up Online University (HOOU). pp. xix–xx. Retrieved 2 November 2018.

- Al-Hussaini, A.A. (2014–2015). "5: Undercarriage (Landing Gear) Layout Blueprint" (PDF). Aircraft Design. University of Technology, Iraq: Mechanical Department/Aeronautical Branch. Retrieved 14 Nov 2018.

- "Aircraft Systems: Aircraft Wheels". AeroSavvy. October eight, 2019.

DOWNLOAD HERE

Labor to Replace Nose Gear Doors on Mooney UPDATED

Posted by: edwardmundint.blogspot.com

Labor to Replace Nose Gear Doors on Mooney UPDATED. There are any Labor to Replace Nose Gear Doors on Mooney UPDATED in here.